R6 FAQ - (Updated 11-26-14)

This thread is a work in progress; it hopefully will answer any question about the 06+ R6 Exhaust and Fuel Controllers and even contains PCV, PCIII, and Bazzaz Maps.

The Cliff Notes for those that don't want to read. Although I strongly recommend you take the time to read the sections below.

Section I - Fuel Controllers

Section II - Maps

Section III - Exhaust 06+

Section IV - PCV and Software

Section V - PCV AutoTune

Section VI - FlashTune Flash Interface

Section VII - Installs

Section VIII - R6 Maintenance

Section IX - Sprockets and Chains

Section X - Suspension

- Suspension Settings

This thread is a work in progress; it hopefully will answer any question about the 06+ R6 Exhaust and Fuel Controllers and even contains PCV, PCIII, and Bazzaz Maps.

The Cliff Notes for those that don't want to read. Although I strongly recommend you take the time to read the sections below.

Section I - Fuel Controllers

- Why do I need a fuel controller

- How they work

- Do I need a fuel controller

- PCV vs. Bazzaz

- Other options

- My Two Cents

- FlashTune Interface vs PCV / Bazzaz

Section II - Maps

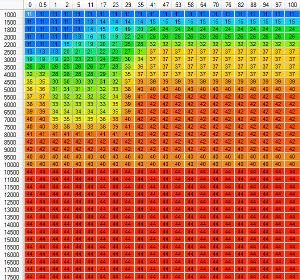

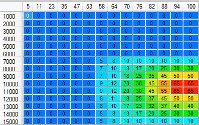

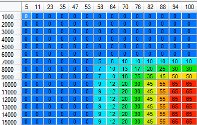

- Choosing a Map

- PCV Maps

- PCV Maps with AutoTune Tables

- PCIII Maps

- Bazzaz Maps

- FlashTune Maps

- Zero Maps (PC and Bazzaz)

Section III - Exhaust 06+

Section IV - PCV and Software

- Calibrating Throttle Position

- Enabling AutoTune

- Setting Target AFR Tables (Also applies to Bazzaz)

- Firmware Updating

- Separate Maps for each Gear

Section V - PCV AutoTune

- Why AutoTune changes never stop

- Separate Maps for each Gear

- When to accept trims

- Using trims as suggestions

- Troubleshooting

Section VI - FlashTune Flash Interface

- Before working with FlashTune please read my warning here.

- Warning

- Original FlashTune Thread

- FlashTune Interface vs PCV / Bazzaz

- Factory ECM Limitations

- FlashTune Software

- Software Versions

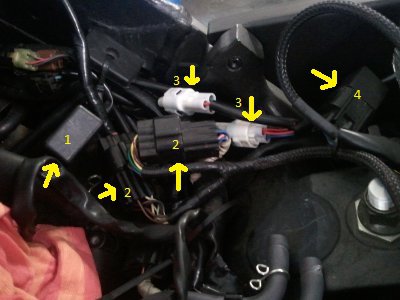

- Using / Installing the Device

- Troubleshooting / Connection Issues

- Timing Recommendations

Section VII - Installs

Section VIII - R6 Maintenance

Section IX - Sprockets and Chains

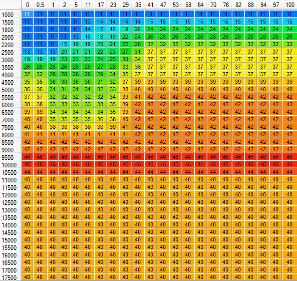

- Sprocket / Ratio Changes

- Chain / Replacement Size

- Rivet Links

- 520 vs 525 vs 530

- Sprocket Material

- Wear / Maintenance

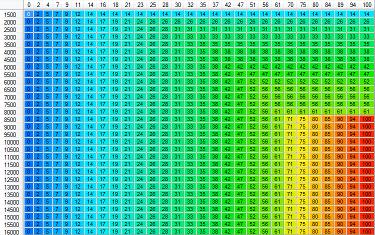

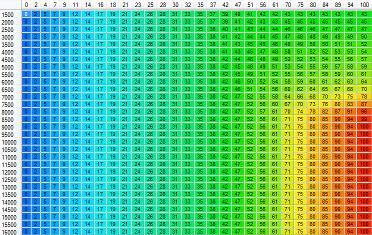

- Speedometer Correction

Section X - Suspension

- Suspension Settings